December 2022. Southwest Airlines—the poster child for lean, efficient operations—collapsed spectacularly. Over ten days, they canceled 16,000 flights, stranded millions of passengers, and burned through more than $1 billion. The culprit wasn’t the winter weather that initially disrupted flights. Other airlines faced the same storms and recovered within days.

Southwest’s failure was systemic: an organization optimized for efficiency with minimal backup systems, skeleton IT infrastructure, and routing designed for perfect conditions. When disruption hit, their lean model became a catastrophic liability. Their crew scheduling system, built for normal operations, couldn’t handle the complexity of reassigning displaced staff. What started as weather delays cascaded into operational paralysis.

Meanwhile, airlines with redundant systems—backup crew bases, flexible routing capabilities, robust IT infrastructure—weathered the same storms and returned to normal operations quickly. The difference? They had built strategic abundance into their systems, not artificial scarcity.

This principle applies whether you’re running a Fortune 500 company, a 20-person startup, or a community nonprofit. Scale doesn’t change the fundamental truth: when your organization depends on single points of failure—one key person, one critical system, one essential relationship—you’re building brittleness, not strength.

Why Redundancy Actually Works

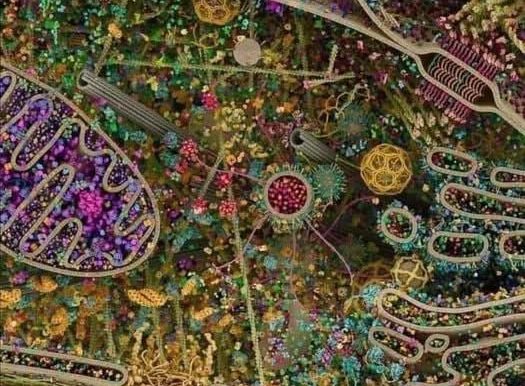

Nature figured this out millions of years ago. Your immune system doesn’t run lean—it produces billions of white blood cells daily, most of which never fight infection. Forests don’t optimize for efficiency—they maintain multiple species performing overlapping functions so the ecosystem survives when individual species struggle.

Research from high-reliability organizations (air traffic control, nuclear plants, emergency response) shows that redundant systems don’t just prevent failures—they enable innovation. When people know backup exists, they take smarter risks and push boundaries.

Google’s Project Aristotle found that psychological safety—partly created by knowing support systems exist—was the strongest predictor of team performance across the organization.

The Generosity Advantage

Here’s where redundancy creates an unexpected competitive edge: it enables organizational generosity. When you’re running lean, every request for help becomes a zero-sum calculation. Can we spare this person for that project? Do we have time to mentor the new hire? Can we take on that strategic initiative?

Lean organizations say no by default. They have to—any additional commitment threatens their carefully optimized operations. This creates a scarcity culture where teams hoard resources, avoid collaboration, and resist helping other departments.

Organizations with redundancy say yes more often. They can lend expertise to struggling teams, take on ambitious projects, invest time in developing people, and pursue opportunities that don’t fit neatly into existing workflows. This abundance mentality attracts top talent, builds stronger partnerships, and creates a culture of mutual support.

The most innovative companies understand this principle. Google’s famous “20% time” (where engineers could spend one day a week on side projects) was only possible because they built redundancy into their engineering capacity. Netflix can experiment with new content formats because they maintain surplus technical and creative resources. These companies don’t see extra capacity as waste—they see it as fuel for generosity and innovation.

When your organization has breathing room, you can afford to be generous with time, attention, and resources. That generosity compounds into stronger relationships, better opportunities, and more resilient networks—advantages that lean competitors can never match.

The Psychology of Efficiency Addiction

So if redundancy works so well, why do smart leaders keep falling into the efficiency trap? The answer lies in powerful psychological drivers that make lean thinking irresistibly attractive.

The control illusion drives much of this behavior. Efficiency metrics feel manageable and precise—”we reduced headcount by 15%” sounds concrete and measurable. But resilience is messier. How do you quantify the value of systems that prevent disasters that never happen? Leaders gravitate toward what they can control and measure, even when those metrics don’t predict long-term success.

There’s also powerful status signaling at work. “I run a tight ship” has become a badge of leadership honor. Cutting costs and eliminating “waste” signals competence to boards, investors, and peers. There’s no equivalent status boost for building redundancy because its value only becomes visible during crises—which smart leaders hope to avoid.

Leaders also love the hero narrative of “doing more with less.” It’s dramatic, challenging, and makes them the protagonist who overcame resource constraints through brilliant optimization. Building redundancy lacks this narrative appeal—there’s no glory in having extra capacity you may never need.

Quarterly pressure compounds these psychological forces. Efficiency improvements show immediate results on financial statements, while redundancy investments often look like costs until they prevent a catastrophe. In a world of quarterly earnings calls and annual reviews, leaders face enormous pressure to optimize for short-term metrics over long-term resilience.

Finally, there’s simple fear of judgment. Leaders worry that building redundancy will be seen as wasteful or indecisive. “Why do you need two people who can do that job?” sounds like a reasonable question from someone focused on cost control. It’s easier to justify lean operations than to explain the value of strategic abundance.

These psychological drivers create what researchers call “efficiency bias”—the systematic preference for optimization over resilience, even when resilience would deliver better long-term outcomes.

The Real Cost of “Efficiency”

Here’s what lean operations actually cost organizations:

Healthcare Systems: During COVID-19, hospitals with “just enough” staffing collapsed while those with redundant capacity adapted and continued serving patients.

Manufacturing: Toyota’s lean supply chains created massive vulnerabilities during the 2011 tsunami, while companies with supplier diversity recovered faster.

Nonprofits: Organizations dependent on single major donors face existential crises when funding disappears, while those with diversified revenue streams survive and grow.

Startups: Companies with only one person who understands critical systems regularly face crises when that person leaves or becomes unavailable.

Addressing the Money Objection

“We can’t afford redundancy.”

The question isn’t whether you can afford redundancy—it’s whether you can afford not to have it. Most leaders dramatically overestimate the cost of building redundancy while underestimating the price of brittleness.

Consider the free and low-cost options first. Cross-training costs time, not money—simply pair experienced staff with others on critical tasks. Documentation creates backup knowledge systems that cost only time to maintain. Developing multiple vendor relationships before you need them requires relationship building, not budget increases. Even comprehensive cloud backups often cost less than $50 per month for most organizations.

The math consistently favors redundancy. Take a small nonprofit: training two people to manage the donor database costs about 20 hours. But one week without access during unexpected staff turnover costs 40+ hours of recovery time plus potential donor relationships. For a startup, cross-training two developers on critical systems costs one week of time. But hiring an emergency contractor during a crisis costs $5,000+ and delays product launches. In manufacturing, establishing a backup supplier relationship costs initial setup time, while a production shutdown costs $10,000+ per day.

The pattern is clear: modest investments in redundancy consistently prevent disproportionately expensive disasters.

Handling Common Objections

“Redundancy kills agility.” This reflects a fundamental misunderstanding of what creates speed. Organizations with redundancy actually move faster because they’re not paralyzed by fear of failure. When you know backup systems exist, you can experiment boldly and recover quickly from mistakes. Redundant systems enable rapid experimentation, not bureaucratic slowdown.

“Our investors want lean operations.” Smart investors want sustainable operations, not brittle ones. Show them the Southwest example—$1 billion in losses because lean thinking created systemic vulnerability. Investors who push for dangerous efficiency over strategic resilience are optimizing for short-term metrics that destroy long-term value.

“We’re too small for redundancy.” Actually, small organizations are more vulnerable to single points of failure, making redundancy more critical, not less. When a 20-person company loses their only person who understands a critical system, the impact is proportionally devastating. Small organizations can’t absorb failures the way large ones can—they need redundancy most of all.

“Redundancy creates bureaucracy.” Bureaucracy comes from complex processes and approval layers, not from backup capabilities. Well-designed redundancy actually simplifies operations under stress by providing clear alternatives when primary systems fail. The goal isn’t to add complexity—it’s to add resilience.

The Strategic Advantage

Organizations that embrace strategic redundancy don’t just survive disruption—they thrive through it. While competitors scramble during crises, redundant organizations maintain operations, serve stakeholders, and often gain market share.

The future belongs to antifragile organizations that get stronger under stress. Building redundancy isn’t preparing for failure—it’s creating the conditions for breakthrough success.

Stop asking: “How little can we operate with?” Start asking: “How much resilience can we build into our systems?”